Sample Production & Grading

Pattern Grading & Size Development Services

At AttireXGlobal, we understand that precision in pattern grading is the bridge between a single sample and a fully scalable clothing line. Our goal is to ensure every garment, regardless of fabric, type, or size, fits perfectly, feels natural on the body, and reflects the true identity of your fashion brand.

We combine years of craftsmanship with advanced CAD-based software, delivering an accurate, efficient, and globally recognized grading system. From the first measurement to the final size chart, we transform each pattern into a production-ready asset that’s consistent, reliable, and technically sound.

Whether you’re manufacturing shirts, pants, dresses, jackets, or knitwear, AttireXGlobal provides the digital foundation to make your apparel fit every customer with ease and confidence.

What Is Pattern Grading and Why It Matters

Pattern grading is the process of increasing or decreasing a pattern’s dimensions to create a complete range of sizes. It’s what allows one beautifully fitting sample garment to become a full-scale collection.

In the modern fashion industry, the art of grading has evolved from manual paper methods to intelligent CAD systems. These digital tools follow precise mathematical rules that preserve accuracy, fit, and proportion across every pattern piece.

At AttireXGlobal, we treat grading as a science of measurement and an art of balance. A difference of a few millimeters in shoulder width, sleeve length, or hip curve can alter the way a shirt, sweater, or pair of pants feels on the wearer. Our graders apply refined grading rules to maintain harmony across all sections of the garment, ensuring uniformity in fabric behavior, stretch, and comfort.

Our Approach to Size Development

Pattern Making → Digitizing → Grading → Production

Every fashion brand has a unique audience and identity — that’s why there’s no “one rule fits all.”

We develop brand-specific size charts and grading systems based on:

- Your target market (US, EU, UK, or custom)

- Regional sizing standards

- Your desired fit profile (slim, relaxed, oversized, etc.)

Our team studies human body data, industry benchmarks, and past sample performance to build a truly personalized sizing model.

The process begins with your approved base size (e.g., M or US 8) and expands into a full range — XS to XXL or beyond — while maintaining perfect balance in silhouette, ease, and comfort.

Our grading software ensures mathematical precision, while our experts apply decades of manufacturing experience to preserve the emotional connection between clothing and the wearer.

Understanding Grading Rules & Measurement Accuracy

Before any scaling begins, we define detailed grading rules that specify exactly how much width, length, or ease each size should gain or lose.

Using specialized rulers and advanced CAD systems, our graders adjust every critical point:

- Shoulder width

- Chest & waist circumference

- Sleeve & inseam length

- Hip curve and ease allowance

But here’s what truly sets us apart: grading rules are not universal. They’re tailored to how your fabric behaves.

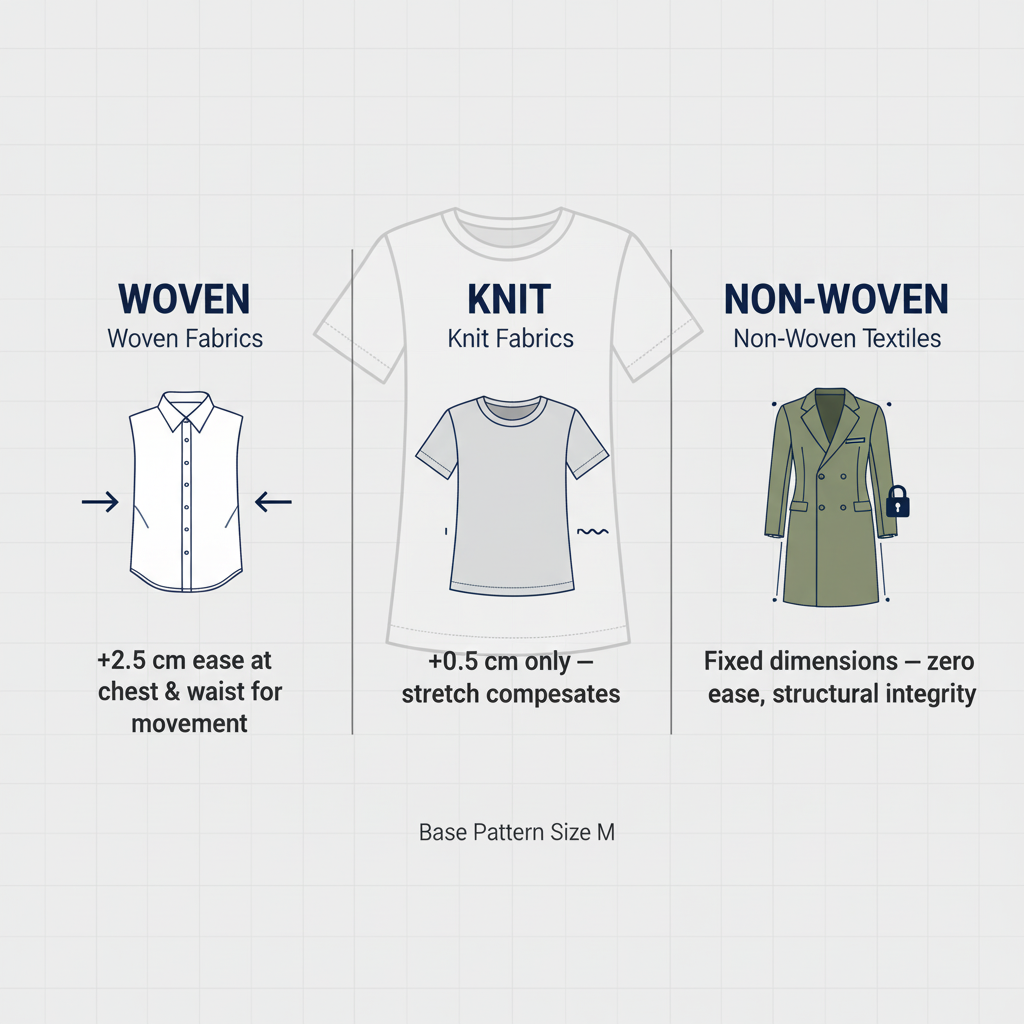

Fabric-Specific Grading in Practice:

- Woven fabrics (e.g., shirts, jackets): Require more ease for natural movement

- Knit fabrics (e.g., t-shirts, leggings): Need less grading — the stretch does the work

- Non-woven textiles (e.g., outerwear, PPE): Demand structural precision to maintain shape

CAD & Software-Based Grading

Gone are the days of tracing paper and manual rulers. At AttireXGlobal, every grading process runs through advanced CAD software that eliminates human error and accelerates turnaround time.

Our system imports your existing pattern data from the pattern making stage, applies custom grading rules, and exports precise size charts ready for manufacturing. These CAD programs visualize pattern shifts in real time, helping our technicians verify alignment, accuracy, and fabric flow before production.

Whether your design involves knit leggings, polo shirts, or structured jackets, digital grading guarantees proportional scaling without distortion. The same platform also integrates with our marker making and cutting room operations — reducing waste and maintaining a fully connected process from design to garment.

The Grading Process at AttireXGlobal

Our grading process blends technology with craftsmanship. Here’s how it works:

📐 Pattern Analysis & Base Size Selection

We begin with your approved pattern from Group 1 and verify measurements against your chosen fit model.

📊 Setting Grading Rules

Our digital graders apply brand-specific increments for each size, ensuring proportional scaling.

💻 CAD Execution

The pattern is loaded into our CAD system, where software automates precise expansions or reductions.

✅ Accuracy Verification

Digital checks confirm that seams, darts, and stitch lines align perfectly between all sizes.

📋 Chart Development

Final size charts are produced for sampling and production use.

👕 Sample Testing & Feedback

We create a physical garment to validate comfort, fabric response, and fit.

Fabric and Fit Adjustments for Every Material

Different fabrics behave differently — and our grading reflects that.

A woven textile requires more ease, while knitted sweaters, t-shirts, or leggings demand tighter control to maintain shape. We analyze each material—from lightweight cotton to stretch spandex, from non-woven fabric to delicate silk—before finalizing grading rules.

Our experts test the fit of each category:

- Pants, pullovers, and cardigans for lower-body flexibility

- Jackets and shirts for shoulder balance and sleeve alignment

- Dresses and swimwear for curvature adjustment

- Innerwear, underwear, and sportswear for elastic precision

By customizing grading for each garment type, we guarantee that the final clothing feels tailored — no matter the fabric composition.

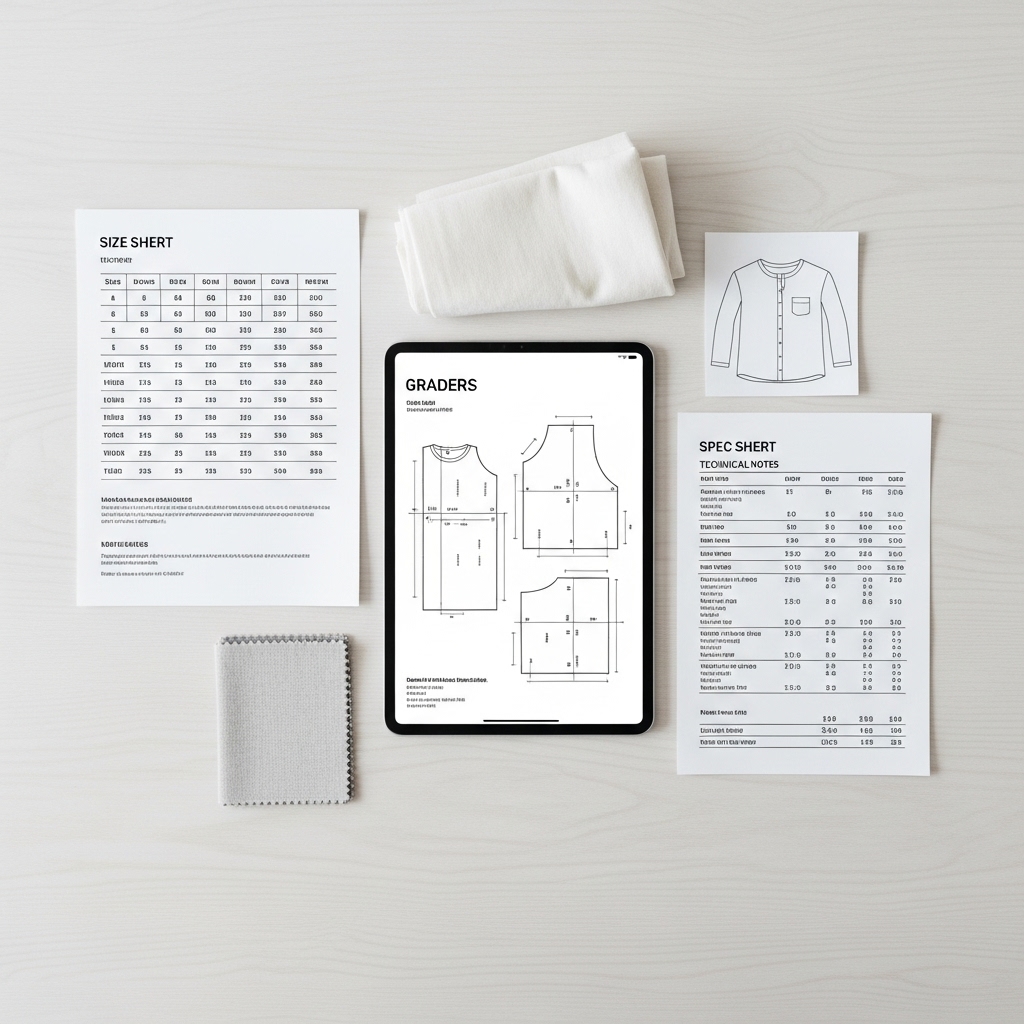

Deliverables You Receive

When you partner with AttireXGlobal, you don’t just receive a graded file — you receive a complete production solution.

Deliverables Include:

📁 Fully Graded Digital Patterns

📏 Custom Size Charts & Spec Sheets

⚙️ Defined Grading Rules

🔗 Seamless System Integration

🧵 Expert Technical Consultation

Tools and Technology Ensuring Accuracy

Precision comes from tools as well as experience.

CAD Software

Industry-standard platforms for automated scaling and fit visualization.

Digital Rulers

Virtual measurement for seam lines and curve control.

Measurement Systems

Body-scanning tools for precise chart generation.

Testing and Validation

Physical and digital checks for every graded pattern.

Why Brands Choose AttireXGlobal for Pattern Grading

AttireXGlobal has earned its reputation as a trusted partner in the global apparel manufacturing industry by combining craftsmanship, data, and technology.

- Accuracy You Can Trust: Each grading process is checked using automated CAD algorithms and human review.

- Comprehensive Services: From pattern making and digitizing to grading, marker planning, and final production.

- Experienced Graders: Our team has years of hands-on expertise in garment and textile engineering.

- Fabric Specialization: Whether it’s knit, woven, or non-woven, we adjust grading rules for each material.

- Global Fit Standards: Our charts and measurements align with international fashion markets.

By partnering with AttireXGlobal, you gain access to a team that understands both the mathematics of accuracy and the emotion behind a perfectly fitting outfit.

Integration with Pattern Making and Manufacturing

Our grading department works closely with the pattern making and manufacturing teams to ensure a seamless transition from design to mass production.

The same CAD system and software used in our Group 1 process are shared across departments, ensuring consistency and traceability for every file.

Once your graded patterns are approved, they move directly to marker making for fabric optimization, and then to cutting and sewing.

This closed-loop workflow reduces errors, saves material, and supports our commitment to sustainable manufacturing.

Integration with Pattern Making and Manufacturing

At AttireXGlobal, we believe that well-graded clothing empowers people to look and feel their best.

Our continuous investment in CAD technology, skilled graders, and fabric analysis sets a new standard for precision in apparel manufacturing. From the first pattern draft to the final production run, we guarantee that every garment — whether a casual t-shirt, luxury jacket, or sports legging — matches your brand’s identity and your customer’s expectations. Choose AttireXGlobal for pattern grading services that combine accuracy, efficiency, and artistry.

We don’t just grade patterns — we grade your brand for global success.