Pattern Making

Pattern Making, Digitizing & Marker Services

At AttireXGlobal, we understand that a flawless garment begins with an accurate pattern. From emerging fashion labels to global apparel brands, our clients trust us to transform creative designs into ready-to-produce templates using modern CAD, digitizing, and marker technology. Every pattern is the blueprint of your brand’s quality, and we treat it as a science — backed by experience, craftsmanship, and the power of technology.

As a leading pattern making company, we combine fashion industry knowledge with advanced digital systems to bring your vision to life. Our in-house studio is equipped with computerized tools that ensure precision in fit, fabric usage, and production consistency. Whether you’re developing a capsule collection or managing full-scale manufacturing, AttireXGlobal offers the infrastructure and expertise to make it happen.

We work all over Los Angeles County and Orange County. From Anaheim to Long Beach, Santa Ana to Pasadena, we’ve got you covered.

The Foundation of Every Great Design

Pattern making is not just a technical step — it’s the foundation of your entire manufacturing process. The accuracy of a pattern determines how well your garment fits, drapes, and performs. Our pattern makers begin with a detailed development plan based on your design, fabric, and custom specifications.

Every pattern is crafted with a balance of creativity and geometry, ensuring each garment aligns with your brand’s silhouette, movement, and fit. Using CAD systems, we generate precise digital patterns that maintain consistency across styles and sizes. This fusion of artistic design and digital accuracy is what makes AttireXGlobal’s pattern making services stand out globally.

We serve a wide range of fashion, apparel, and garment industries, from boutique designers to large-scale manufacturers. Each pattern undergoes strict review, ensuring it meets the same standards of excellence that define our brand.

Digitizing — Bridging Craftsmanship with Technology

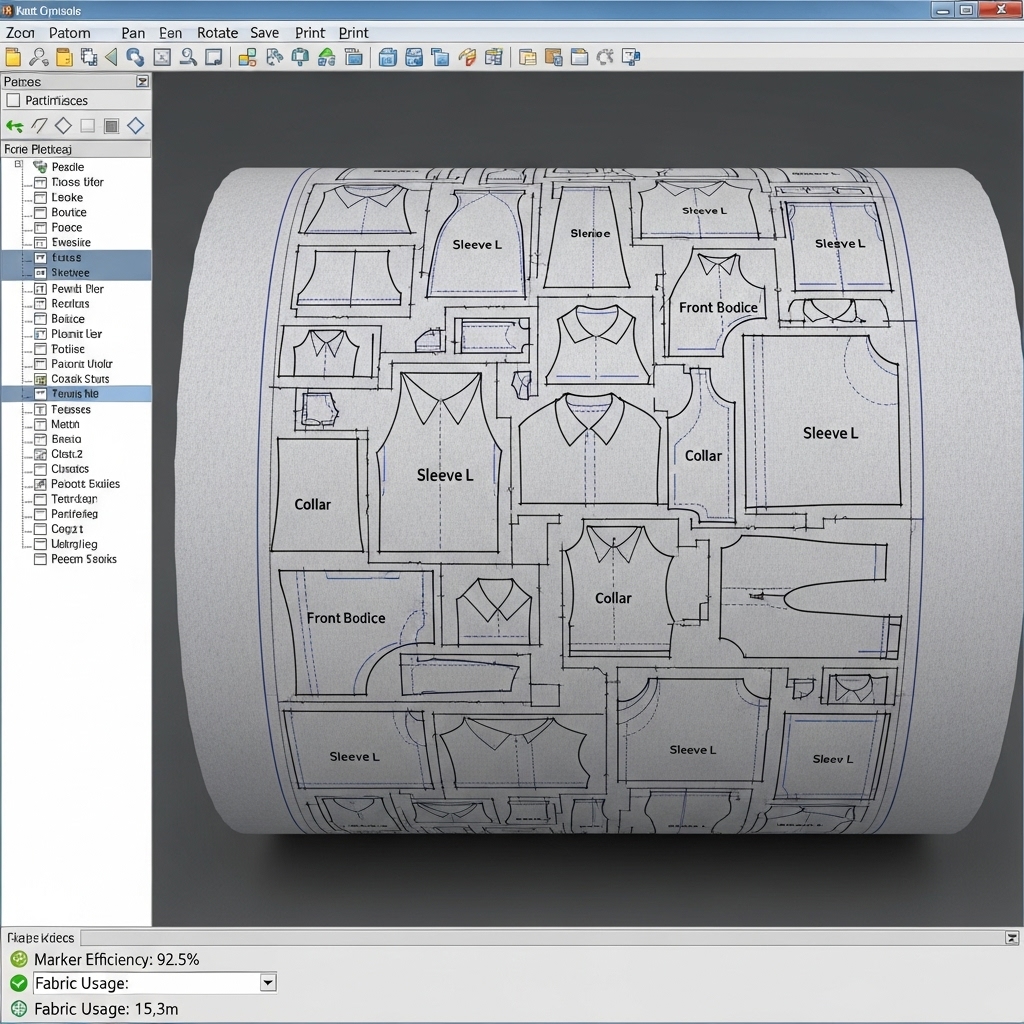

Once a physical pattern is ready, the next step is digitizing — converting traditional paper patterns into digital formats using advanced CAD and digitizer tables. This process allows for faster editing, cleaner storage, and seamless integration into the marker making and grading stages.

Our digitizing software captures even the finest details — notches, grainlines, seam allowances, and marker layout references. These digital patterns are stored within our system, ready for updates, scaling, or future modifications.

By using computerized CAD technology, we eliminate manual errors and improve communication between designers, patternmakers, and manufacturers. It also helps optimize fabric use during cutting, ensuring every inch of material serves a purpose.

In addition, our digitizing service supports multiple file formats compatible with the world’s leading apparel manufacturing systems. Whether you’re working from New York, London, or Karachi, our files integrate seamlessly into your production process.

Marker Making — Where Efficiency Meets Accuracy

A pattern is only as good as its first sample. At AttireXGlobal, we transform your digital patterns into tangible prototypes using high-quality fabric and professional sewing techniques. Our sample making team ensures that every prototype reflects your desired fit, style, and product intent.

We follow a meticulous production process: cutting, stitching, pattern scoring, and visual inspection. Each sample undergoes multiple fit tests to check accuracy and wearability before being approved for mass production.

This iterative approach helps refine both design and pattern — saving time and material costs later in the manufacturing cycle. It also gives designers the opportunity to evaluate proportions, silhouette, and fabric behavior under real conditions.

Our sample makers work closely with CAD engineers and production pattern teams to ensure seamless integration of feedback into future batches. This creates a loop of constant improvement — an essential part of AttireXGlobal’s quality-first vision.

Plotting & Printing — Bringing Digital Files to Life

Once your marker and pattern are digitally finalized, they move to our plotting and printing stage. Here, digital precision meets physical execution. Using industrial pattern printers and eco-friendly inks, we transfer each pattern onto durable paper for cutting and sewing.

Our plotting services use computerized systems that ensure each line, curve, and measurement is perfectly replicated. The printed outputs serve as the final visual guide for the production pattern, ensuring a flawless transition from digital plan to physical fabric.

Sample Making & Fit Testing

A pattern is only as good as its first sample. At AttireXGlobal, we transform your digital patterns into tangible prototypes using high-quality fabric and professional sewing techniques. Our sample making team ensures that every prototype reflects your desired fit, style, and product intent.

We follow a meticulous production process: cutting, stitching, pattern scoring, and visual inspection. Each sample undergoes multiple fit tests to check accuracy and wearability before being approved for mass production.

This iterative approach helps refine both design and pattern — saving time and material costs later in the manufacturing cycle. It also gives designers the opportunity to evaluate proportions, silhouette, and fabric behavior under real conditions.

Our sample makers work closely with CAD engineers and production pattern teams to ensure seamless integration of feedback into future batches. This creates a loop of constant improvement — an essential part of AttireXGlobal’s quality-first vision.

Technology, CAD, and In-House Control

Technology drives everything we do. AttireXGlobal uses the latest CAD software and computerized systems to achieve unmatched accuracy. Every pattern, marker, and plotting file is verified using advanced software checks that identify potential fit or layout issues before the first fabric cut.

Because we operate a full in-house pattern studio, all stages — from pattern design to digitizing to printing — remain under one roof. This centralized control enhances communication, protects confidential specifications, and reduces turnaround time.

Our technology doesn’t replace craftsmanship; it enhances it. Behind every digital pattern is a team of human experts — pattern makers, designers, and apparel technicians — who bring years of experience to the process. Together, they ensure each garment meets both creative and technical expectations.

This synergy between digital precision and human skill defines our vision for the modern fashion industry. It’s how we maintain consistency across multiple products, ensure fit accuracy, and uphold the brand promise of being a “top-notch service” provider.

Sustainability & Optimization

As part of our eco-conscious approach, AttireXGlobal focuses on optimization and minimal waste.

♻️ Smart Fabric Use

Our marker making and plotting systems automatically calculate the most efficient fabric plan, reducing scrap by up to 25%

🌱 Eco-Friendly Materials

We promote the use of recycled paper for pattern printing and encourage clients to use eco-certified fabrics wherever possible.

🤝 End-to-End Responsibility

Every process — from digitizing to cutting — is managed to minimize environmental impact while keeping quality uncompromised. Being a modern apparel manufacturer means thinking beyond aesthetics.

Seamless Link to Pattern Grading

Pattern Making → Digitizing → Grading → Production

After your pattern has been approved and digitized, the next logical step is pattern grading — converting a single base size into multiple sizes that fit various body types. This ensures your design retains its proportions and integrity across all sizes and markets.

Our grading division operates on the same CAD systems, allowing quick and precise data transfer between departments. By maintaining one unified system, we ensure complete consistency between your pattern making, digitizing, grading, and production cycles.

This seamless connection means you can easily scale your fashion line without repeating the design work. Whether you need grading rules, size charts, or factory-ready templates, we provide everything under one brand umbrella — AttireXGlobal.

Why Choose AttireXGlobal

AttireXGlobal is more than a pattern making service — we’re your strategic partner in the full fashion manufacturing journey. With a global footprint, a modern in-house studio, and decades of technical expertise, we’re trusted by brands worldwide for precision, reliability, and seamless execution.

We combine craftsmanship, technology, and end-to-end control — so you get more than just patterns. You get peace of mind.

- Precision-Driven Patterns

- Full In-House Control

- Seamless Integrated Workflow

- Decades of Industry Experience

- Transparent & Timely

At AttireXGlobal, we don’t just make patterns — we make possibilities.

Every marker, every digitized file, every graded size reflects our commitment to craftsmanship, innovation, and your brand’s success.